Product Description

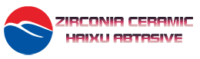

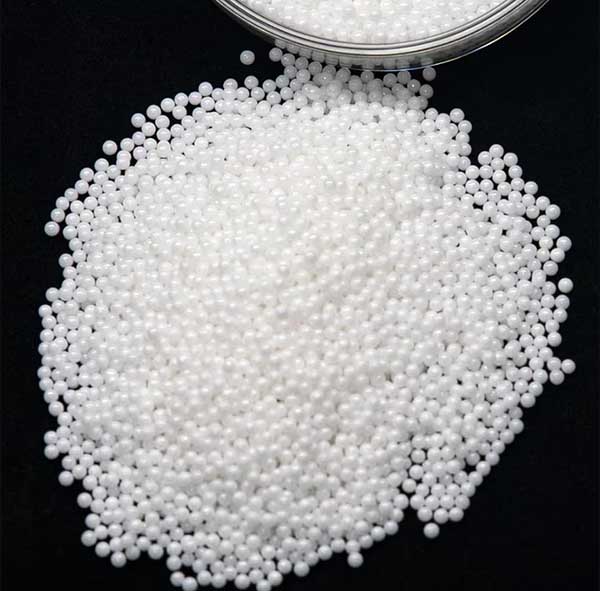

Zirconium Oxide Beads

The content of zirconia in the beads is approximately 95% so it is usually called “95 Zirconium” or “Pure zirconia beads”. With the rare earth yttrium oxide as stabilizer and the raw material of high whiteness and fineness, there will be no pollution to the grinding material.

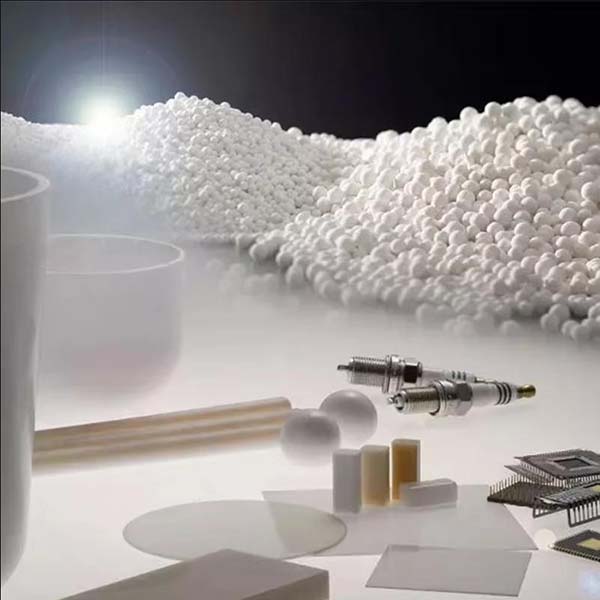

The zirconium oxide bears are used for superfine grinding and dispersing of zero pollution, high viscosity, high hardness and so on. It is applied to the equipment like horizontal sand mills, vertical sand mills, basket mills, ball mills and attritors.

Physical and Chemical Indicators

Product Parameters | ||

Categories | Units of Measurement | Value |

Composition | wt% | 94.6%ZrO2,5.4Y2O3 |

Specific density | g/cm3 | ≥5.95 |

Hardness(HV) | HRA | >10 |

Thermal expansion | X10-6/K | 11 |

Coefficient(20400) | ||

Elastic modulis | GPa | 205 |

Fracture toughness | Mpa·m1/2 | 7-10 |

Bending strength | MPa | 1150 |

Grain size | Um | <0.5 |

Thermal conductivity | w/(m·k) | 3 |

Our Advantages

Advantages

1. High density ≥ 6.02 g/cm3

2. High wear and tear resistance

3. With low contamination of the grinding product, zirconium oxide beads are suitable for high-grade grinding of pigments, dyes,

pharmaceutical and cosmetic products

4. Suitable for all modern types of mills and high energy mills (vertical and horizontal)

5. Excellent crystal structure avoids bead breakage and reduces the abrasion of mill parts

Application Scenario

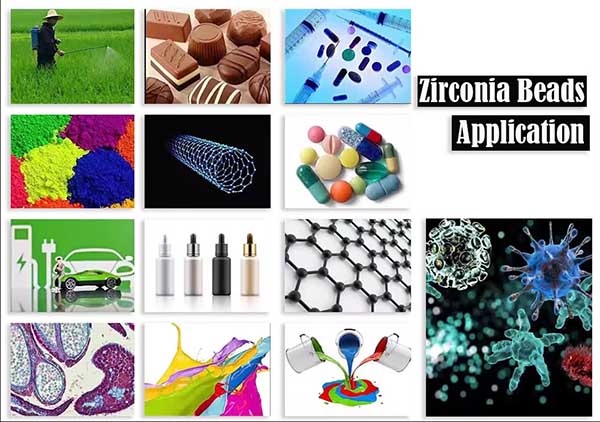

1. Bio-tech (DNA, RNA & protein extraction and isolation)

2. Chemicals including Agrochemicals e.g. fungicides, insecticides and herbicides

3. Coating, paints, printing and inkjet inks

4. Cosmetics (Lipsticks , Skin & sun protection creams)

5. Electronic materials and components e.g. CMP slurry, ceramic capacitors, lithium iron phosphate battery

6. Minerals e.g. TiO2, Calcium Carbonate and Zircon

7. Pharmaceuticals

8. Pigments and dyes

9. Flow distribution in process technology

10. Vibro-grinding and polishing of jewelrys, gemstones & aluminum wheels

11. Sintering bed with good thermal conductivity, can sustain high temperatures