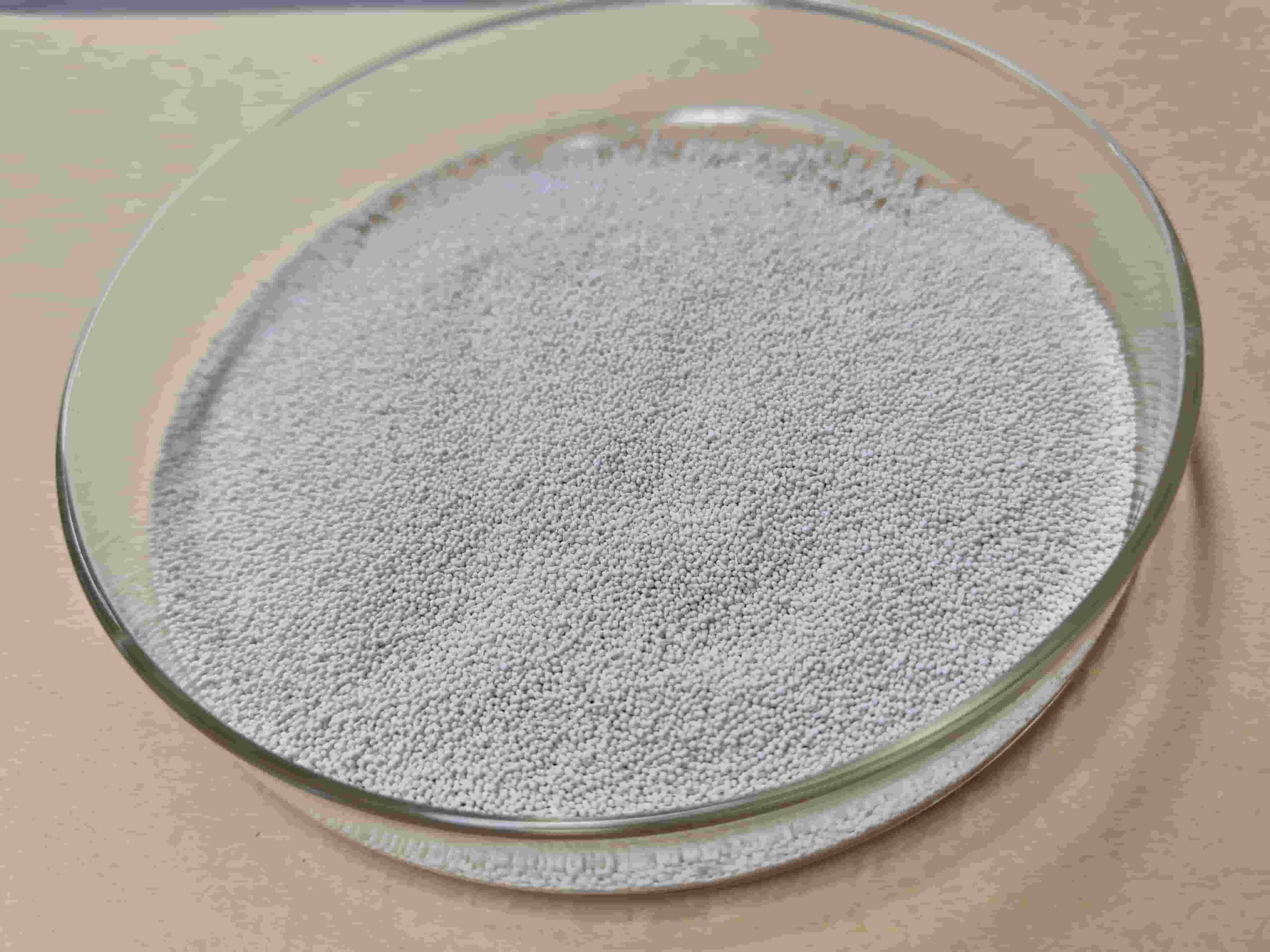

0.125-0.18 mm Size B100 Ceramic Beads Blasting Media Stainless Steel Surface Finish

Ceramic beads blasting media is a new environment friendly sandblasting material, it can be used to replace of glass beads, about 12 times longer working life than glass beads, no dust, no iron pollution, good toughness, good wear resistance and excellent performance in sandblasting finish for metals like alu, alu alloy, Titanium alloy, magnesium alloy, steel, stainless steel etc.

Our ceramic beads are of good toughness, good wear resistance and impact resistance, which ensures consistent surface finishes.

2. Specification

| Technical Data | |||

| Components | Content | CAS No. | EC No. |

| ZrO2 (Zirconium dioxide) | 60-68% | 1314-23-4 | 215-227-2 |

| SiO2 (Silicon dioxide) | 25-30 | 60676-86-0 | 262-373-8 |

| Al2O3 (Aluminum oxide ) | 7-13% | 1344-28-1 | 215-691-6 |

| Manufacturing Method | Melting in above 2000℃ furnace | ||

| True Density | 3.85 g/cm3 | ||

| Bulk Density | 2.3g/cm3 | ||

| Vicker Hardness | 700HV | ||

| Sizes for Sand Blasting | |||

| Bead Size | Size range | Bead Size | Size range |

| B20 | 0.60-0.85 mm | B120 | 0.063-0.125 mm |

| B30 | 0.425-0.60 mm | B125 | 0.000-0.125 mm |

| B40 | 0.24-0.425 mm | B170 | 0.045-0.090 mm |

| B60 | 0.125-0.25 mm | B205 | 0.000-0.063 mm |

| B80 | 0.180-0.25 mm | B400 | 0.030-0.063 mm |

| B100 | 0.125-0.18 mm | B505 | 0.000-0.030 mm |

| Sizes for Shot Peening | |||

| Z850 | 0.85-1.18 mm | Z210 | 0.21-0.30 mm |

| Z600 | 0.6-0.85 mm | Z150 | 0.15-0.21 mm |

| Z425 | 0.425-0.60 mm | Z100 | 0.10-0.15 mm |

| Z300 | 0.30-0.425 mm | ||

3. Applicaiton

Surface finish for metal parts to achieve one satin blasting effect;

Surface preparation for electroplating or anodizing to achieve a certain surface roughness;

Surface finish for medical instruments to remove the microburrs and make small round conners at the

junctions of two surface to finally achieve the most smoothness texture;

Surface reinforcement for automotive parts to eliminate the surface stress and improve the surface strength.

4. Applicable Equipments of Ceramic Beads

1)Manual sand blasting machine

2)Annual Sand blasting Machine

3)Sandblasting room