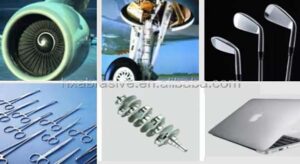

Why Ceramic Beads is especially Suitable for Metal Surface Finish?

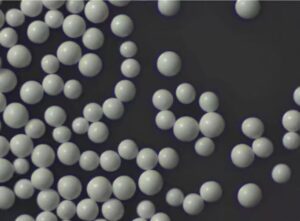

Ceramic Beads Blasting Media has the outstanding characteristics of smooth surface, good elasticity and high hardness,which can be rebounded from multiple angles in blasting application, especially suitable for metal surface finishing treatment.